“Reliable Fobrubber Factory Teflon Lip Seal: Ensuring Leak-proof Sealing Solutions for Industrial Applications”

At our fobrubber factory, we specialize in crafting high-quality Teflon lip seals that offer superior performance and durability. Our reliable seals are designed to prevent leaks and contamination in a wide range of industrial settings, providing peace of mind to our customers.

“Fobrubber” Factory is a trusted manufacturer in China with years of experience in producing high-quality teflon lip seals for various industries. Our products undergo strict quality control measures to ensure durability and reliability.

Our factory offers competitive pricing and flexible customization options to cater to the unique needs of each buyer. We are committed to providing excellent customer service and timely delivery to all our clients.

By choosing “Fobrubber” Factory, buyers can benefit from our advanced manufacturing technology and skilled workforce, ensuring top-notch products that meet international standards. Our teflon lip seals are designed to withstand harsh operating conditions and deliver optimal performance.

Furthermore, we prioritize transparency and honesty in all our business dealings, cultivating long-term relationships with our customers based on trust and mutual respect. Our dedicated team is always ready to address any inquiries or concerns promptly and efficiently.

Using this technique, we turn flat metal sheets into different parts by bending, perforating, cutting, and designing. Every sheet metal can be transformed into many different forms. However, we carefully select the materials. We used high-end aluminum sheets, steel sheets, stainless steel, brass, and more. According to your exact specifications, we guarantee high-precision car sheet metal parts.

In a professional way, KDM can work with you anytime you need sheet metal components and our services. We are a well-established company with wide experience working with automotive businesses worldwide. Here, we assure you can get premium parts at fair prices. Contact us today!

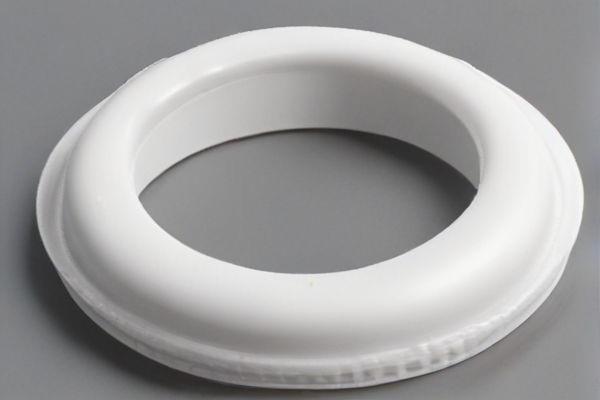

A Teflon lip seal is a type of sealing device used to prevent leakage in industrial applications. These seals are resistant to high temperatures and chemicals, making them ideal for harsh environments.

– Types of Teflon lip seals: spring-loaded, non-spring loaded

– Options: different sizes, material options (e.g. PTFE, Teflon-coated rubber)

– Customizable designs for specific applications

– Can withstand extreme temperatures and pressures

– Easy installation and maintenance

– Long service life

– Cost-effective solution for sealing needs in various industries.

We used these materials for creating bulkheads, dashboards, and other car parts because of their malleability, softness, and lightweight properties. They also produce attractive polish and do not corrode, unlike other materials. We made them unbreakable as well. However, car parts made of aluminum are the most recommended ones, especially if you need durable parts for car repair or custom interior restoration.

A Teflon lip seal is commonly used in industrial applications to prevent leakage and ensure a tight seal in various equipment such as pumps, mixers, and compressors. Its high chemical resistance and low friction properties make it ideal for use in harsh environments.

– Preventing leakage in pumps, mixers, and compressors

– Maintaining a tight seal in industrial equipment

– High chemical resistance and low friction properties

– Ideal for use in harsh environments

The process is used in modifying and customizing automobile components. It is also required for precise roll-bar fabrication, vintage reconditioning, fixing or restoration process, and body reforming. So, if you are part of the automotive industry and you need a custom car parts supplier and fabrication professional, choose KDM!

Teflon lip seals have become an essential component for automobile manufacturers and auto component suppliers due to their exceptional performance and durability. These seals are made from a type of polytetrafluoroethylene (PTFE) material that offers high resistance to heat, chemicals, and wear. The low friction properties of Teflon lip seals make them ideal for use in various automotive applications, including engine components, transmissions, and hydraulic systems. By incorporating Teflon lip seals into their products, automobile manufacturers can improve the overall performance and reliability of their vehicles, leading to increased customer satisfaction and loyalty.

Teflon lip seals are a common choice for industrial equipment manufacturers due to their exceptional durability and chemical resistance. These seals are made from high-quality Teflon material, which is known for its non-stick properties and ability to withstand harsh environments. When used in industrial equipment, Teflon lip seals can effectively prevent leaks and contamination, ensuring the smooth operation of machinery. The low friction coefficient of Teflon also helps to reduce wear and tear on the equipment, prolonging its lifespan and reducing maintenance costs for manufacturers.

High-Tech and Specialty Application companies often rely on teflon lip seals for their advanced sealing needs. These high-performance seals are made of specialized teflon material that offers exceptional chemical resistance, making them ideal for industries working with corrosive substances. The teflon lip seal is also known for its low friction properties, ensuring a smooth and efficient operation in high-speed applications. Its ability to withstand extreme temperatures and pressure makes it a reliable choice for companies operating in demanding environments, such as aerospace, automotive, and pharmaceutical industries.

Teflon lip seals are a crucial component in medical devices and equipment for medical supply companies and manufacturers. These seals are designed to provide a reliable and efficient barrier between moving parts in devices, ensuring that fluids or contaminants do not leak or interfere with the device’s operation. Teflon is a highly durable and chemically resistant material, making it ideal for use in medical applications where cleanliness and precision are essential. The low friction properties of Teflon also make it an excellent choice for ensuring smooth and consistent operation of medical devices, reducing the risk of wear and tear over time.

Teflon lip seals are widely used in electronics and electrical equipment manufacturing due to their highly durable and chemical resistant properties. These seals are typically made of polytetrafluoroethylene (PTFE), a synthetic material known for its low friction coefficient and ability to withstand extreme temperatures. In electronic applications, teflon lip seals are commonly used to prevent contamination from entering sensitive components such as motors and switches. The non-stick properties of teflon also make it ideal for applications where a smooth surface is necessary for optimal performance.

A Teflon lip seal is a high-performance sealing solution commonly used in various industries by Custom Solutions and Innovative Product Development Companies. Made from polytetrafluoroethylene (PTFE), Teflon lip seals offer excellent resistance to heat, chemicals, and abrasion, making them ideal for applications where traditional rubber seals may fail. Their low coefficient of friction also ensures smooth operation and long-lasting performance, even in harsh environments.

Custom Solutions and Innovative Product Development Companies often choose Teflon lip seals for their versatility and durability. These seals can be custom-designed to fit specific dimensions and requirements, allowing for precise sealing in a wide range of applications. Whether used in automotive, aerospace, or industrial machinery, Teflon lip seals provide a reliable and efficient sealing solution that helps improve overall product performance and longevity. With their high resistance to wear and tear, Teflon lip seals are a popular choice for companies looking to enhance the quality and reliability of their products.

The Fobrubber Teflon lip seal is made from a combination of rubber and Teflon materials. The rubber provides flexibility and durability, while the Teflon adds a slick surface for smooth sealing.

Rubber is a versatile material that is known for its elasticity and resistance to wear and tear. It is perfect for creating a tight seal that prevents leakage of fluids or gases.

Teflon is a non-stick material that is commonly used in cookware due to its ability to repel liquids. When combined with rubber, it creates a seal that is both durable and effective at preventing leaks.

The Fobrubber Teflon lip seal is ideal for applications where a strong and reliable seal is needed. Its combination of rubber and Teflon materials ensures that it can withstand high pressures and temperatures without compromising its sealing capabilities.

The quality control manufacturing process for fobrubber teflon lip seals begins with inspecting raw materials for consistency and durability. This ensures the final product will meet specifications.

Next, the seals are precision machined to ensure accurate dimensions and proper fit. This step is crucial in preventing leaks and ensuring the seal functions properly.

Once machined, the seals undergo a series of tests to ensure they meet industry standards. This includes pressure testing, leak testing, and temperature testing to confirm reliability.

In addition, all seals go through a visual inspection to detect any imperfections or defects. Any non-conforming seals are rejected to maintain quality standards.

In conclusion, the quality control manufacturing process for fobrubber teflon lip seals is rigorous and thorough to ensure that each seal meets the highest standards of performance and reliability. By carefully monitoring each step of the process, manufacturers can guarantee a product that consistently meets customer expectations.

The Fobrubber Teflon Lip Seal is a high-quality sealing solution designed to provide superior performance in various industrial applications. With a combination of rubber and Teflon materials, this seal offers exceptional resistance to heat, chemicals, and pressure.

The rubber material of the Fobrubber Teflon Lip Seal provides flexibility and durability, ensuring a tight seal even in high-pressure environments. The Teflon lip further enhances the seal’s performance by reducing friction and improving sealing efficiency.

This seal is ideal for use in pumps, compressors, and other equipment where reliable sealing is critical. Its ability to withstand a wide range of temperatures and pressures makes it a versatile solution for demanding industrial applications.

Overall, the Fobrubber Teflon Lip Seal offers exceptional sealing capabilities that help improve equipment performance and reliability. Its innovative design and durable materials make it a cost-effective and long-lasting solution for a wide range of industrial sealing needs.

By providing car sheet metal fabrication, we can create different car parts with excellent precision. All final auto components are engineered according to your requirements. Each part is perfect for car restoration, repair, and replacement.

We are fully capable of producing unique yet cheaper customized pieces. We are supported with advanced machines, including pipe benders, stretchers, cutting tools, and more. With more than decades of experience, KDM delivers precision and aesthetics to your projects.

A Teflon lip seal offers many benefits to various industries due to its exceptional properties. Known for its high resistance to extreme temperatures and chemicals, as well as its low friction coefficient, a Teflon lip seal ensures superior performance and durability.

– High resistance to extreme temperatures and chemicals

– Low friction coefficient for smooth operation

– Excellent wear resistance for long-lasting performance

– Superior sealing capabilities to prevent leaks and contamination

– Compatible with a wide range of fluids and gases

– Easy to install and maintain for cost-effective solutions

– Suitable for a variety of applications such as automotive, aerospace, and industrial machinery.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

Teflon lip seals are known for their exceptional wear and chemical resistance, making them ideal for high-performance applications. Their low-friction properties reduce heat generation and increase efficiency.

– High wear resistance

– Chemical resistance

– Low friction

– Reduced heat generation

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

Fobrubber specializes in custom-made Teflon lip seals for a variety of industrial applications. These specialized seals are designed to provide optimal sealing performance in demanding environments.

Our team works closely with clients to develop custom seal solutions that meet their specific requirements. Whether it’s a unique size, shape, or material composition, we have the expertise to provide a customized solution that fits your needs.

From design to production, our team ensures that each Teflon lip seal meets the highest quality standards. Using advanced technologies and materials, we are able to create durable and long-lasting seals that provide superior performance under challenging conditions.

Fobrubber has successfully completed numerous custom seal projects for clients across various industries. Our track record of delivering high-quality products and meeting tight deadlines has earned us a reputation as a trusted supplier in the industry.

Fobrubber Teflon Lip Seal is a leading manufacturer of high-quality lip seals made from durable Teflon material. With years of experience in the industry, Fobrubber has gained a reputation for producing reliable and efficient lip seals that are used in a wide range of applications. Their seals are designed to provide a tight and secure seal, preventing leaks and ensuring smooth operation. Fobrubber’s commitment to quality and innovation has made them a trusted partner for many industries, including automotive, aerospace, and manufacturing. Customers can rely on Fobrubber Teflon Lip Seal for superior performance and long-lasting durability, making them a top choice for all sealing needs.

The automotive industry utilizes teflon lip seals in various components of vehicles to ensure efficient operation and prevent leaks. Teflon lip seals are commonly used in areas such as engines, transmissions, and power steering systems where a high level of sealing performance is required. These seals are made from a durable material that is resistant to chemicals and high temperatures, making them ideal for use in harsh automotive environments. Teflon lip seals provide a reliable barrier that prevents fluids from leaking out and contaminants from entering critical components, ensuring the longevity and performance of the vehicle.

Teflon lip seals have been widely used in industrial and manufacturing applications due to their excellent durability, chemical resistance, and low friction properties. These seals are commonly used in machinery such as pumps, compressors, and hydraulic systems to prevent leakage of fluids and gases. The Teflon material used in the lip seal ensures a tight and reliable seal that can withstand high temperatures and pressures, making it ideal for harsh industrial environments. The low friction properties of Teflon also help reduce wear and tear on machinery parts, extending their lifespan and reducing maintenance costs.

The Teflon lip seal is a high-performance application used in various industries due to its exceptional durability and resistance to extreme temperatures and harsh chemicals. The Teflon material provides a smooth surface that reduces friction and wear, making it ideal for sealing applications in demanding environments. Its ability to maintain a tight seal even in high-speed and high-pressure conditions makes it a reliable choice for industrial machinery, pumps, and hydraulic systems.

One of the key benefits of the Teflon lip seal is its long service life and low maintenance requirements, which result in cost savings for businesses. The Teflon material is also non-reactive and inert, making it compatible with a wide range of fluids and chemicals without corroding or deteriorating over time. Its superior sealing performance helps prevent leaks and contamination, ensuring the efficient and reliable operation of equipment. Overall, the Teflon lip seal offers high-performance capabilities that meet the demanding requirements of modern industrial applications, making it a valuable component in various industries.

Teflon lip seals are commonly used in the medical and health industry for a variety of applications due to their durability and chemical resistance. These seals are often utilized in medical devices such as pumps, valves, and other equipment where a tight seal is necessary to prevent leaks and contamination. Teflon lip seals are also known for their ability to withstand high temperatures and harsh chemicals, making them ideal for use in sterilization and cleaning processes within healthcare facilities.

In addition to medical devices, teflon lip seals are also used in pharmaceutical manufacturing equipment to ensure product purity and prevent cross-contamination. The non-reactive nature of teflon makes it an ideal material for sealing applications in pharmaceutical production, where maintaining product integrity and compliance with regulatory standards is crucial. The use of teflon lip seals in the medical and health industry helps to enhance safety, reliability, and efficiency in various processes, ultimately contributing to better patient care and overall health outcomes.

Teflon lip seals are commonly used in the electronics and electrical industry for a variety of applications. These seals provide excellent resistance to chemicals, high temperatures, and wear, making them ideal for protecting delicate electronic components from contamination. In electronic devices such as sensors, switches, and connectors, teflon lip seals serve as reliable barriers that prevent dust, moisture, and other foreign particles from entering the electronic components and causing damage. The low friction properties of teflon also help to reduce wear and ensure smooth operation of moving parts in electrical devices, increasing their durability and lifespan.

General Manufacturing and Custom Solutions often use teflon lip seals in their equipment and machinery for various applications. Teflon lip seals are known for their durability, resistance to high temperatures, and chemical compatibility, making them ideal for use in harsh industrial environments. These seals are commonly used in pumps, valves, and other mechanical components to prevent leakage of fluids and gases, ensuring efficient operation and minimal downtime.

In General Manufacturing, teflon lip seals are widely used in equipment such as mixers, conveyors, and compressors to ensure reliable performance and prevent contamination of the final product. Custom Solutions providers also rely on teflon lip seals to create specialized sealing solutions for unique applications. These seals can be customized to fit specific dimensions and requirements, allowing for seamless integration into complex machinery and systems. Overall, teflon lip seals play a crucial role in maintaining the performance and reliability of equipment in various industries, making them a valuable component in the manufacturing and custom solutions sectors.

What is a Teflon lip seal and what is its purpose in manufacturing?

A Teflon lip seal is a sealing device made of synthetic material that is used to prevent leaks and contamination in machinery and equipment. It is commonly used in manufacturing processes to maintain the quality and efficiency of the products being produced.

What are the benefits of using Teflon lip seals in manufacturing?

Teflon lip seals have a number of advantages, including high temperature resistance, chemical resistance, and low friction properties. This makes them ideal for use in manufacturing processes where harsh conditions are present.

How can I ensure the quality of Teflon lip seals from a FOBrubber factory?

To ensure the quality of Teflon lip seals from a FOBrubber factory, it is important to conduct thorough research on the company and their manufacturing processes. Look for certifications and quality control measures in place to guarantee a high standard of production.

Manufacturing Teflon lip seals at a rubber factory requires careful planning and precision to ensure high-quality products. Here are some tips to consider when manufacturing Teflon lip seals:

1. Use high-quality Teflon material: It is essential to source high-quality Teflon material to ensure the durability and performance of the lip seals.

2. Precision in cutting and molding: The Teflon material should be cut and molded with precision to achieve the desired shape and dimensions of the lip seal. Use advanced machinery and tools to ensure accuracy.

3. Proper lubrication: Teflon is known for its low friction properties, but proper lubrication is still important to prevent excessive wear and tear on the lip seal.

4. Quality control: Implement a strict quality control process to inspect each Teflon lip seal for defects, such as cracks or deformities. This will help maintain the high standards of the product.

– 1. What is a Teflon lip seal and why is it needed? A Teflon lip seal is a type of sealing component that is often used in machinery to prevent leakage of fluids or gases. It is made from Teflon, a material known for its durability and resistance to high temperatures and chemicals. The lip seal is designed to create a tight seal between moving parts, such as a piston and cylinder, to ensure that no fluid or gas escapes.

– 2. Why source a Teflon lip seal from a FOB Rubber factory? FOB Rubber is a reputable and experienced manufacturer of rubber and plastic products, including Teflon lip seals. By sourcing the lip seal from FOB Rubber, you can be assured of high-quality materials and precision manufacturing techniques. FOB Rubber’s factory can also provide customized solutions to meet your specific requirements.

When searching for a teflon lip seal from a fobrubber factory, there are several tips that can help streamline the sourcing process.

1. Start by conducting a thorough online search for fobrubber factories that specialize in manufacturing teflon lip seals. Utilize search engines and industry-specific directories to find potential suppliers.

2. Reach out to industry contacts or professional networks for recommendations on reputable fobrubber factories that produce teflon lip seals. This can help narrow down your search and ensure you are connected with a reliable supplier.

3. Request samples or product catalogs from multiple fobrubber factories to compare the quality and pricing of their teflon lip seals. This will allow you to make an informed decision based on your specific needs and budget requirements.